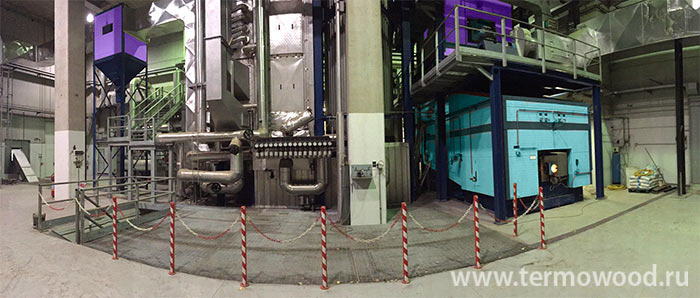

Cogenerational mini-CHP on biofuel

Our company carries out the design and implementation of mini-CHP projects that produce electricity and heat using two alternative technologies:

- Cogeneration plants with turbines ORC cycle;

- mini-CHP stations with steam turbines high and medium temperature and pressure.

We realize projects of biofuel mini-CHP "turnkey": from the development of the concept of building the power plant to the production, delivery and installation of a cogeneration unit at the facility with carrying out commissioning. The produced power, usually ranges from 15 kWe to 500 MWe.

Mini-CHP with ORC turbine

ORC turbogenerator is designed to convert the heat energy coming through the thermal oil circuit from the boiler into electricity and thermal energy heating water. The principle of operation is based on the idea of a closed thermodynamic Organic Rankine Cycle (ORC).

The work of boiler and turbine generator are automated and do not require a permanent location in the engine room personnel, both in normal operating conditions and in emergency situations. In the event of a malfunction trouble-free turbine generator is disconnected from the mains. The unit has a thermal oil circuit. The rated speed of the turbine corresponds to the nominal speed of the generator (direct drive connection diagram).

The advantages of CHP with ORC turbine:

- high efficiency of the cycle;

- very high turbine efficiency (up to 90%);

- low mechanical load of the turbine due to low linear velocity;

- low turbine speed enables direct control of the electric generator without reduction gear;

- no erosion of the plates due to the lack of moisture in the steam nozzle;

- simple start and stop;

- automatic and continuous operation;

- no need for the constant presence of the operator;

- it runs quietly;

- high availability;

- at partial load of 10% of the rated capacity;

- high efficiency even at partial load;

- low maintenance requirements: about 3-5 hours per week;

- long service life.

Mini-CHP with steam turbine

The use of mini CHP steam turbines of small capacity makes it possible to quickly and with minimal material investment to reconstruct the existing or construct new energy facilities. Block execution of power plant components, its compact dimensions and weight allow you to quickly engage in the fomer thermal circuit, conducting installation work in existing boilers without any capital construction.

Installation of such turbines in the local points of steam reduction allows to produce energy wich is lost in the normal operating cycle of steam in additional electrical power. And this is possible without major changes in process parameters, i.e., increasing the amount of fuel consumed, changes in heat parameters and existing steam distribution scheme.

Power, the installation location and the type of power units is calculated just below the available input and output parameters of required steam. We have the ability to transform into electrical energy process steam of any parameters with maximum maneuverability of steam circuit without affecting the processes of steam consumption.

The advantages of mini-CHP on biofuel:

- cheap electric and thermal energy;

- economic benefits: reduction of energy consumption in the structure of production costs (for companies);

- reliability and a long service life of cogeneration plants;

- proximity to the customer (the lack of transmission losses and the need to build a distribution network);

- energy independence electricity and heat supply systems;

- little time and flexibility of input into operation;

- quick payback;

- low cost of fuel;

- environmental friendliness.

We offer a comprehensive execution of works — from the implementation of technical expertise and work on the design, to installation and maintenance of the equipment supplied.

Areas of activity:

- economic analysis of technology, development of concepts and proposals;

- technological solutions for the use of biofuels;

- project management.